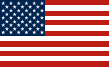

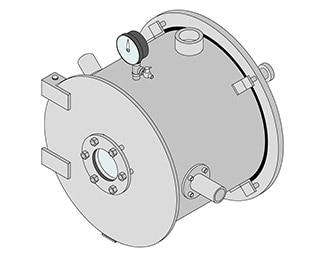

Versator Models

Features of the Cornell Versator

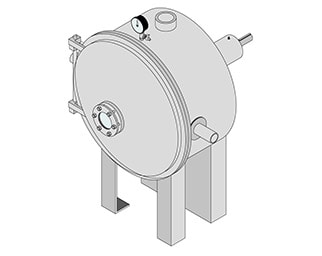

- Removal of entrapped air, foam, or gas from liquids under high vacuum.

- Efficient mixing, blending, homogenization, dispersion, emulsification, removal of moisture or distillation of residuals as a simultaneous secondary benefit.

- The principle of operation is the same for each Versator model size.

- Process virtually any pourable or pumpable liquid – hot or cold – from water to hot chewing gum.

- Heat sensitive and shear sensitive products can be processed.

- Design allows all of the processed material to be exposed in a thin film to high vacuum.

- Continuous operation (no timed cycle) and can be installed in-line or used for batch processing.

- Additional pumps for feed and discharge are not necessary in most installations. Material can be discharged from vacuum chamber by operating design.

- Few spare parts subject to wear and easy access to interior parts for inspection and cleaning.

- Minimal product loss during operation.